Original Title (in Finnish): “Ajaako organisaatiosi lasit jäässä?”

Original Publisher: The Finnish Pharmacists’ Society

Publication: Proviisori Journal 1/2012 (pages 24-26)

The article is the third in a series of three articles providing a general introduction to high-performance process improvement.

——————————————————————————————————————————–

The improvement planning quality and dynamics in many organizations are comparable with a car with zero windows visibility except for one tiny clear area at the rear. Increasing the visibility of the rear window does not improve the visibility of the windshield. Already the data collection method affects which windows areas may be clear. Focusing on wrong issues wastes a great amount of opportunities and resources.

The key issue in process improvement is no more the identification and decrease of quality costs, but the identification and realization of opportunities regarding three closely interrelated wholes. These are the improvement activities, the activities to be improved and the produced output.

The quality costs include all costs due to not producing the output correctly from the outset. There are four types of quality costs: external and internal, appraisal and preventive.

The real quality costs represent 15-75 percent of an organization’s revenue depending on the industry. The reported or perceived quality costs are typically only a fraction of this amount because they cover only a part of all quality costs. Utilizing the quality cost concept it is possible to grip issues related to productivity. This is, however, only the other side of the coin, as one needs to cultivate also the effectiveness.

In high-performance process improvement the opportunities are reviewed based on the gap between the current and desired ambition levels regarding the improvement activities, the processes and the outputs. The ambition level differences can be quantified via three cornerstones, i.e. time, quality and money, the effect of which together form a considerably greater value waste than the quality costs.

The value waste due to lost opportunities is billions on a national level. This waste affects negatively the satisfaction of all stakeholders, and more generally on the employment level, the tax revenues and the well-being. This value waste is many times not disclosed simply because traditional improvement methods and systems do not identify this issue. You cannot know what you do not know.

The Quintet of Process Improvement

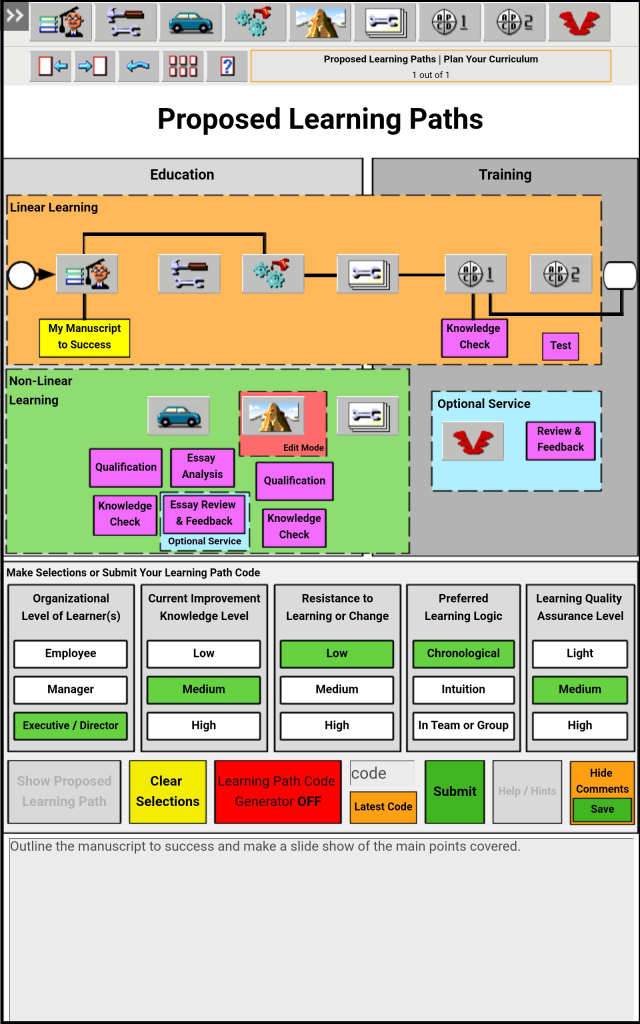

In addition to decreasing waste, quality defects and variation, high-performance process improvement requires that you master many other issues concurrently – with scarce time and money resources. There are five key issues, implemented via a process approach, that provide the solution to this challenge :

- The assurance of the improvement effectiveness and efficiency.

- The management and improvement of the improvement performance at different ambition levels – in addition to improving the performance of the operations.

- The seamless improvement of both the processes and the produced output at ever higher ambition levels – in addition to improving processes or the output in isolation.

- Improving large and complex wholes and networks – in addition to improving local processes or functions.

- Identification and realization of opportunities – in addition to identifying and decreasing quality costs.

An end-to-end perspective regarding the improvement value chain provides concrete means to manage and improve this complex whole in a good way. When the concepts of the Kano model to output development are integrated seamlessly to process improvement work and the required processes that deal with research, development, marketing, sales, production, delivery and after sales of the offered outputs, a great synergy momentum is created compared with applying the concepts of the Kano model in isolation.

Data, Information and Knowledge

The assurance of the improvement effectiveness means that the organization or network is improving the right issues. The key issue is a good enough identification and selection of the improvement objects, considering well enough the affecting circumstances and prerequisites. To do this, knowledge is always required as knowledge is the prerequisite to make decisions. This calls for a sufficiently performing data collection, and the cultivation of data into information, i.e. an analysis, and the cultivation of information into knowledge, i.e. a synthesis.

The performance of the information process used in the improvement value chain determines to a great extent the quality of the improvement activities in practice. A elementary problem in many organizations is a lacking or defect information process. One example of this is the collection and utilization of such data that is easily obtained, but not such data that would be needed. Another common issue is the cultivation of irrelevant or even wrong data into information.

Additional problems emerge when information or emotional reasons form the decision basis. Information lacks from the outset one crucial cultivation phase that provides the understanding of the requirements and total effects of the actions. Data lacks two cultivation phases. Without a high-class synthesis (knowledge) it is impossible to make high-class decisions. Jumping from data to decision making is a big leap. Very few, if any, are able to conduct a non-trivial analysis and synthesis of a sufficient quality only based on the data provided by the performance measurement system.

The meaning of an analysis in an improvement context is not to provide ”nice to know” information, but to serve in a relevant way the synthesis, decision making and the implementation phase. For this reason score cards, satisfaction surveys, maturity and quality award models offer a misleading platform to manage the operations. These approaches may direct thinking in the wrong direction as they do not offer a synthesis but only a partial analysis. A simple “Then what?” question in the different phases of the improvement work helps many times to clarify the thoughts.

Garbage In, Garbage Out

Knowledge is the basis to make decisions. Assuring the improvement effectiveness means assuring the quality of the decisions. A rather small improvement in the decision quality increases the improvement gain considerably. In comparably small improvement efforts tens of decisions are made in the beginning affecting the quality of the data collection (timing, correctness, usefulness, amount, form, place and price), ending via an analysis and synthesis with the selection of the improvement objects and their implementation.

Customer and employee satisfaction surveys represent only a part of the required data, and for this reason it is not always possible, or even reasonable, to utilize this kind of data as such in the improvement work.

The management’s capability to make high-class decisions from a total perspective is affected by, among other issues, the stress and vitality level, interest, know-how, the vision and the potential external and internal pressure. Another person or another management team could end up with a total different solution. Who is right, or is nobody?

If there are problems in the data collection, analysis and synthesis phases, there is an evident risk that the principle “”garbage in, garbage out” will materialize also in the decisions. The problem areas are not often even recognized, which make the problems hard to remove.

From an improvement perspective the first issues an organization needs to focus on are the bad decision quality and the big variation of the decision quality. Implementing the wrong issues wastes a great amount of opportunities and resources. Often is advisable to improve and measure the strategy work and the quality of the created strategy. In large organizations it may also be motivated to evaluate and improve the quality of the improvement project portfolio and the quality of the project approval process.

Building Quality into the Improvement Plans

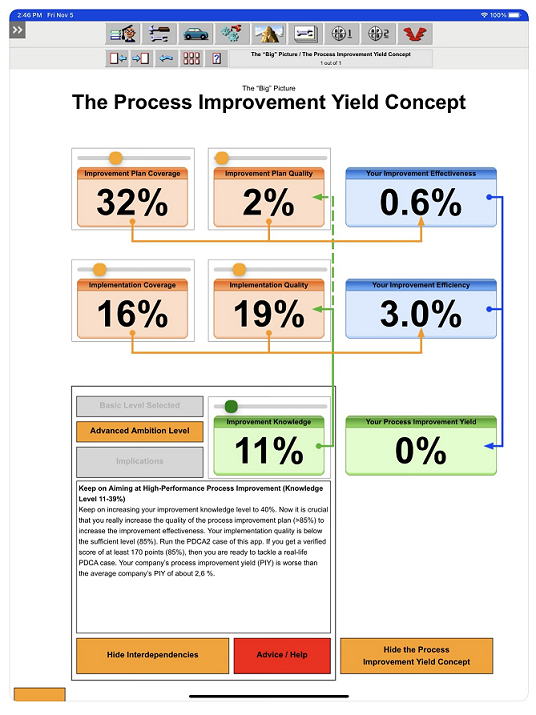

How well an organization is able to consider all crucial improvement aspects can be evaluated well enough based on the written improvement plan. If the quality of a process improvement plan is evaluated at the lowest ambition level, the level is on average 16 percent. This figure is based on the measured average score of 30 companies in the electronics industry. In practice such a level does not support high-class decision making, although such an improvement plan is sufficient for certification purposes.

In real life very few of us would drive with a car anywhere should the visibility of wind shield, side windows and rear window be restricted to one small area at the rear left. The selection of the data collection method and approach decides from the outset what window area can at best be free from visibility obstacles. This affects without a doubt the quality of the analysis and synthesis. If the rear window visibility is improved, this will not affect the visibility of the wind shield to any considerable degree. If clearing the rear windows lasts two hours or the whole day, it is clear that such a performance does not serve anybody. The need and motivation to move may already have vanished in this time frame. Putting in the reverse gear and driving backwards provide no lasting solution, at least when aiming at driving a long distance. This depicts the planning level and dynamics in many organizations.

In car driving, as in improvement work, it is problematic to focus only on one issue as the whole is what matters. In different situations one has to consider and prioritize things right. Without a high-class logic to create high-class improvement plans the organization does what it knows, not what it really should do. When talking about plans, it is utterly important to understand that if only one part of the operations is covered by the plan, then the low planning coverage, e.g. one process out of five, will not provide a sufficient improvement momentum to create a great impact.

Gaining and maintaining a sufficient improvement effectiveness is a very challenging task. The problem cannot be solved without a high-performance logic to create process improvement plans. With modern methods an improvement plan with an 100 percent quality level is achievable in about 14 days consuming less than one working day for the attending key persons.

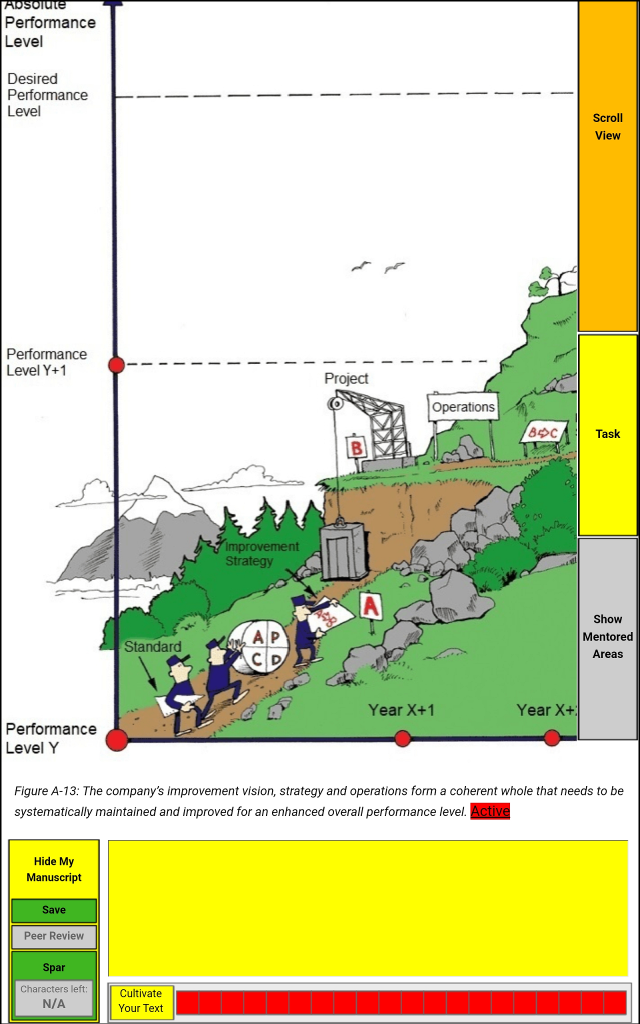

Towards Very Satisfied Stakeholders

The improvement results are not only about improving the absolute performance, but also about improving the relative performance compared with the competitors and other organizations. A higher improvement yield than the reference group improves both the absolute and relative performance. The improvement performance increase is not only counted in euros, seconds or quality defects. The question how much better the organization is able to satisfy the changing and often contradictory needs and requirements of its stakeholders, first and foremost its customers, employees and owners, is more important. The total satisfaction of these three stakeholders is the core that needs to be treasured when improving the operations. If these stakeholders are dissatisfied from a total perspective, then there is no basis to satisfy other stakeholders either. Just remaining in the same spot requires that the improvement work advances with the same speed than the needs and performance requirements increase or change.

Swamp There, Water Here, not Dry Anywhere

The fact that the others improve their operations also with the same low performance level provides only an expensive illusion regarding the current improvement level of the own organization or even a whole industry sector. Increasing the speed in this improvement swamp is not possible without increasing considerably the costs or affecting negatively the quality.

Swamp running is a skills sport where the stumbling and decrease of energy lower the motivation even for a seasoned runner. When the energy level is close to zero, then you find yourself even more far out at the swamp – and lost. This provides the swamp specialists with new opportunities to help the customer out of the mire. This will of course newer happen. After the investment a new, slightly different swamp with mirages will appear.

Wading in the improvement swamp towards new mirages is surprisingly popular. The years pass by, but the same problems, such as e.g. information quality and IT system related problems, remain. In such a mode it is hard to find any positive aspects.

When the performance of the organization is sufficiently bad, or is not improving according to the plan, then the easiest way to tackle the issue is to lower the ambition level, or refer to bad management. The root causes of the problems will not vanish by improving the effects. The structural problems of the improvement methods cannot be fixed with good management.

An Aha! Moment is Needed

Getting on the right track requires embracing a new improvement perspective and often also an Aha! moment. Satisfied customers, employees and owners do not show as such that the organization is performing well. Not until the customers, employees and owners are very satisfied, the right track has been found. In addition, efforts have to be conducted to increase the satisfaction of other stakeholders as well, and to that the mentioned three stakeholders are very satisfied also in the future.

The world, the organizational requirements and improvement needs have change a lot during the past few years, not to mention since the days of the quality gurus. The pace of the change does not show any signs of slowing down. The improvement performance needs special attention during good, mediocre and bad times. A high process improvement yield assures for any organization that this is the case. This simple principle will go a long way. The time for high-performance process improvement is always.